A Surprising Find in a Parker V14-160 Hydraulic Motor ــــ ⏱ 8 min read

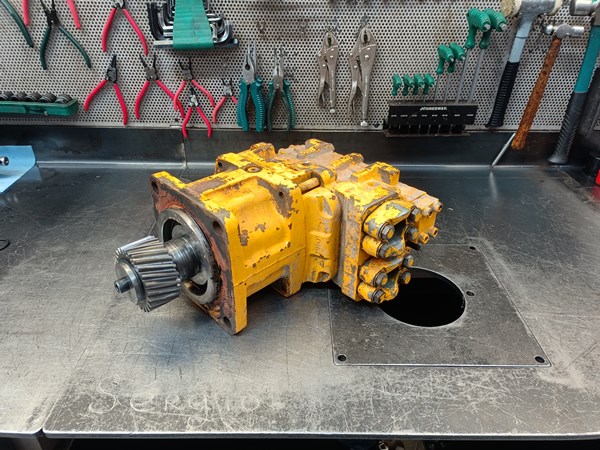

I have a brain-teaser for you, but you do need to know what’s inside of this thing to get it:

This is a Parker V14-160 bent-axis hydraulic motor – and here’s the million-dollar question: “How can a barrel sliding plate that looks like this…”:

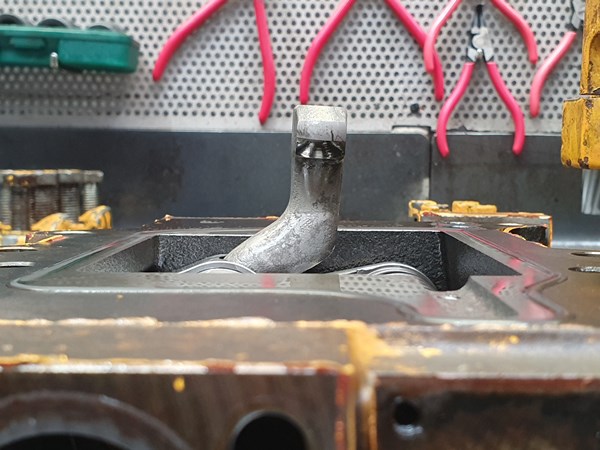

…come out of a hydraulic motor that has a valve segment that looks like this?:”

Let me tell you something else – this motor has at least 2000 hours of confirmed operation with these parts. It ran non-stop for seven months in Portugal, so I am estimating 200 days x 10 hours a day, but it should have more than that for sure, plus nobody knows if this drilling rig did any work before it was brought here.

So… any ideas?

I will show you now how this was possible – take a look at what greeted me as soon as I removed the end plate – I didn’t touch any parts and took these pictures immediately when I saw it:

Taking the hydraulic motor apart for inspection Do you see anything strange here? Wait!.. The bronze face should be facing the other way, should it not? This is what happens when the sliding plate is mounted the other way around This is what happens when the sliding plate is mounted the other way around This is what happens when the sliding plate is mounted the other way around

You are seeing exactly what I’m seeing! And now you also know what happens when you take a sliding plate of the barrel of a V14-160 hydraulic motor and mount it “the other way around” – with the bronze side facing the barrel, and not the valve segment! Once again – this motor ran for at least 2000 hours like that before it was sent to us with a complaint about “excessive drain flow” – which is insane, if you ask me.

The particles originated from the “unconventional” arrangement also did a number on the race of the larger bearing:

The outer race of the bearing presents evidence of raunning with small but hard particles in the oil The outer race of the bearing presents evidence of raunning with small but hard particles in the oil

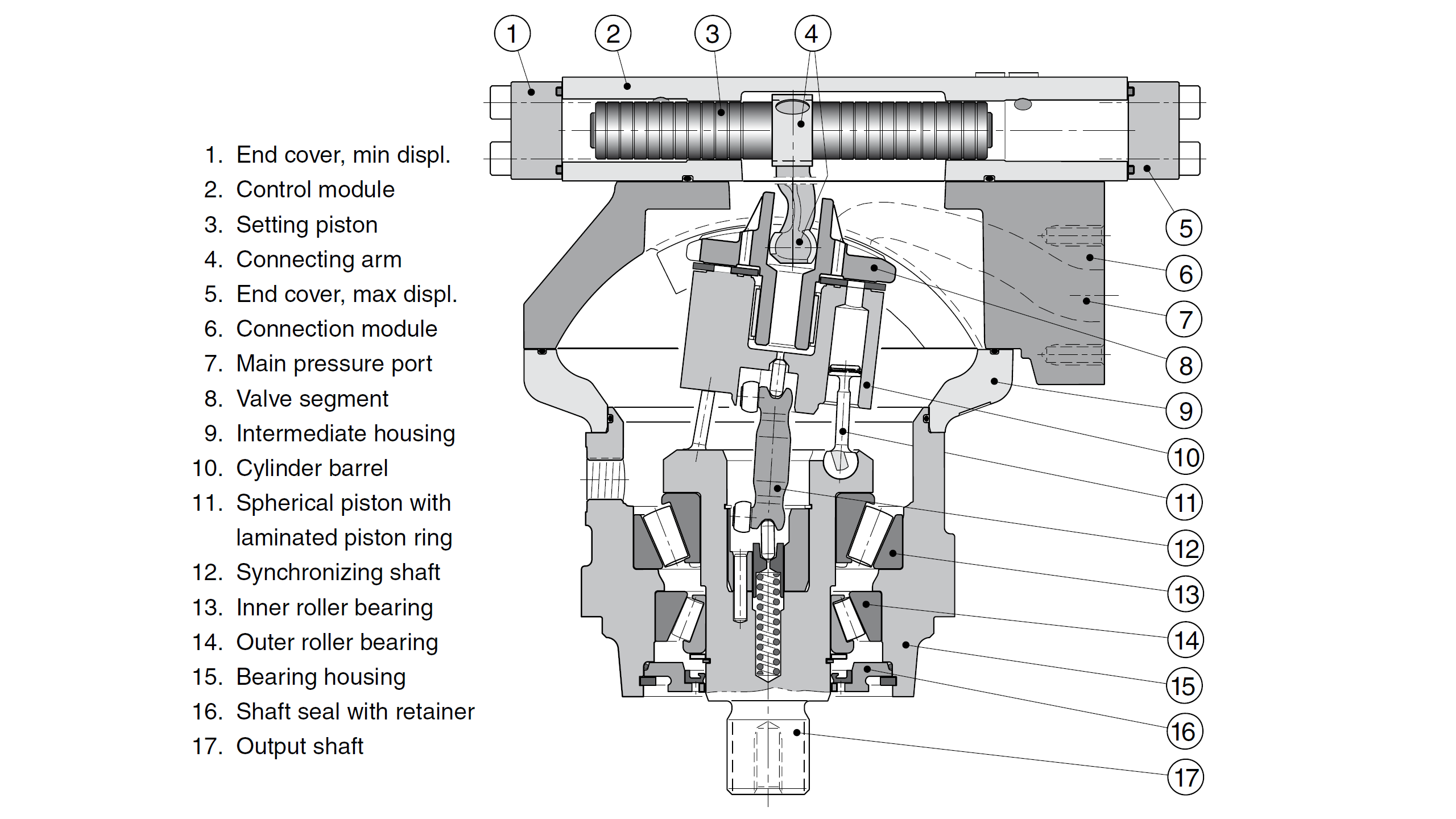

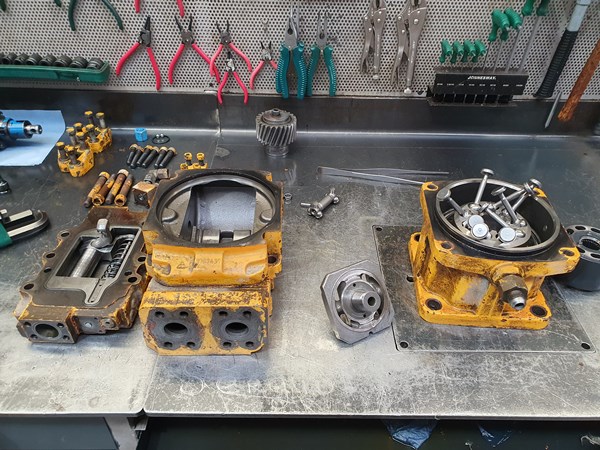

But the rest of the motor is OK, so I think it is still salvageable (even with the monstrously inflated prices for Parker spares in this part of the globe). And now, I want to take this opportunity and say a few words about the design of this motor – because it definitely stands out.

No Pressurized Lubrication of the Piston Ball Joints

If you look at the likes of Rexroth A6VMs or Danfoss H1s, you will see that their pistons have holes in the center that channel pressurized oil to the ball joints – but not the V14! The V14 is a Parker creation, but it is, in essence, a younger brother of the V12. The V12 was originally produced by VOAC (a “marriage” between Volvo Hydraulics and Atlas Copco) and inherited the staple creed of Volvo Hydraulics’ fixed-displacement bent-axis motors: “a ball joint of a piston shall be lubricated by the case oil and case oil only!”

And you know what? It works – and, apparently, very well! Furthermore, the pistons can be easily removed from the sockets, and, as you can see for yourself, even in this heavily abused motor, the spherical surfaces look pretty clean and wear-free:

By the way, their younger and more muscular siblings (220 and 270 cc) – the V16s – employ the same piston design and boast speeds of 4,000+ rpm at partial displacements. This raises the question: are those lubrication channels for spherical piston joints really needed?”

Offset Servo-Piston

Everyone and their mom centers the servo-piston in relation to the segment valve, but not this guy:

When I look at the crooked connecting arm – the word “arthritis” comes to mind, for some reason… They also moved the spool and the feedback springs to the side as well – and let me tell you – this is, by far, the clearest illustration of a spring-feedback-based proportional displacement control I’ve ever seen!

Tapered Roller Bearing Assembly

Unlike the aforementioned competitors, in which the shafts come out as single assemblies with the tapered roller bearings, in the V14 the outer races of the bearings “hug” the housing (making it, essentially, a spacer) which means you need to remove the retaining ring before pressing the shaft out:

So, if you ever catch somebody who’s used to working primarily on A6VMs pounding frenetically on the shaft end of a V14 and wondering why the hell it won’t come out, go near them and see if the retaining ring is still in place. It’s actually all in the service manual, but who reads service manuals, right?

Modular Housing

“Normal” bent-axis motors have bodies that are essentially composed of two parts – the front housing, and the end plate. The V14 has four! – The bearing housing, the intermediate housing, the port and segment valve housing, and the control module housing.

I, actually, love the idea of modularity, and especially the fact that you can replace the segment valve interface on its own (we all know how badly these things wear out). Alas – the prices for the parts are so steep that when you find yourself in need of replacing the segment valve housing – getting a new motor usually makes more sense.

There’s another thing about the hosing that I really appreciate – the fact that this motor does not use any of those annoying specialized gaskets/seal carriers – it only uses classic o-rings (I am looking in your direction, Danfoss, and I am not smiling). They actually even went one step further and included the sizes of the o-rings in the parts manual! This is already awesome, although if they used standard AS568 o-rings it would have been even awesom-er.

Min and Max Displacement Set With Shims

I’ve never liked a shim-based adjustment of anything. I can see why they did it, though – they wanted a compact unit – but I still hate it.

In all – the biggest problem with this motor is the fact that it is … well… a Parker. My love and hate relationship with this brand is well known – they make great products, but their prices are high and spare parts are hard to get (around here, I’m told it’s very different in the US) which is why I tend to steer clear of their stuff unless I have no other options. But the V14 is a solid motor with a unique design that just works.

Source: https://www.insanehydraulics.com/kaboom/parkerv14barrelplate.html

افزودن دیدگاه