Manufacturing Industries ــــ ⏱ 5 min read

Hydraulics in Manufacturing Industries

Hydraulics in manufacturing industries refers to systems that use the power of pressurized fluid to control, transmit power, and operate machinery in production processes. These systems play a key role in production lines, machining, and factory automation due to their ability to generate high force, precise control, and reliability in harsh industrial conditions. From metal forming to component assembly and robotic control, hydraulics are integral to many stages of manufacturing and production of final products.

Applications of Hydraulics in Manufacturing Industries

- Hydraulic Presses:

- Metal forming in processes such as forging, rolling, and extrusion using multi-thousand-ton presses.

- High-precision production of automotive, aircraft, and industrial components.

- CNC Machines and Machining:

- Hydraulic systems for controlling axis movement, fixtures, and tool pressure in lathes, milling machines, and grinders.

- Automatic tool adjustment in advanced machines.

- Industrial Robots and Automation:

- Hydraulic robotic arms for moving heavy parts or performing welding and painting operations.

- Hydraulic systems in automated assembly lines.

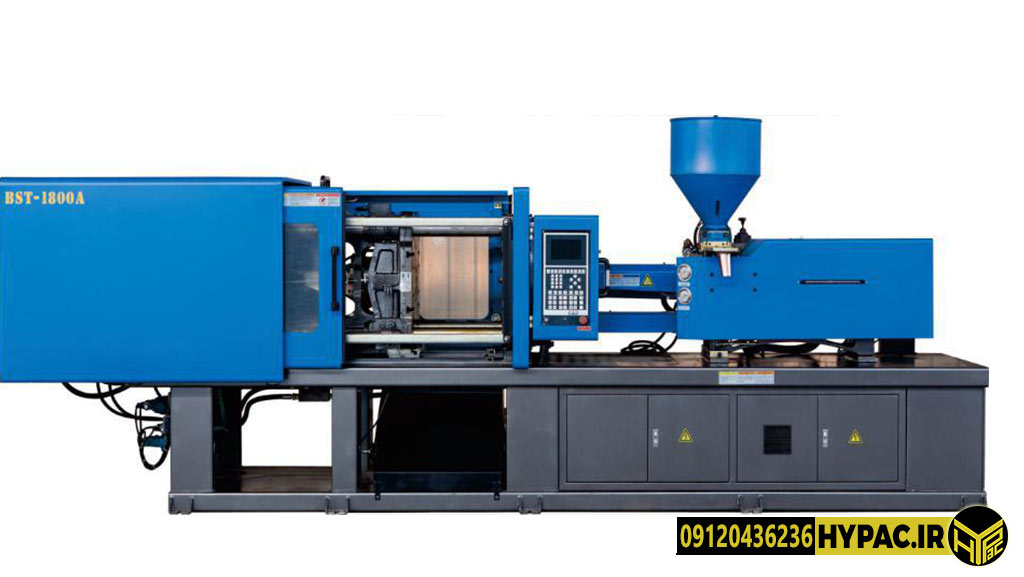

- Plastic Injection and Molding:

- Plastic injection machines with hydraulic systems for applying high pressure during mold filling.

- Precise control of mold temperature and injection speed.

- Material Handling Systems:

- Hydraulic conveyors for transferring parts between workstations.

- Factory cranes for moving raw materials or finished products.

- Industrial Labs and Pressure Testing:

- Use of hydraulic systems for stress testing components (e.g., burst testing of pipes or tanks).

Main Components of Hydraulic Systems in Manufacturing

- High-Pressure Pumps: Generate pressures up to 700 bar for heavy processes (e.g., hydraulic presses).

- Precision Cylinders: Convert fluid energy into linear motion with micron-level accuracy in CNC machines.

- Servo Hydraulic Valves: Precise control of pressure and flow for sensitive operations.

- Accumulators: Store energy to compensate for pressure fluctuations in press or injection systems.

- Heat-Resistant Fluids: Synthetic oils with thermal stability for high-temperature environments.

- Advanced Filters: Prevent metal particles or contaminants from entering the system.

Challenges of Hydraulic Systems in Manufacturing

- High Precision Requirements: Minimal error in machining or robotic systems requires highly precise design.

- Fluid Contamination: Metal particles or dust from production processes reduce system lifespan.

- Costly Repairs: Hydraulic system failures in mass production lines can lead to significant financial losses.

- Integration with Automation: Coordinating hydraulic systems with electronic controllers (e.g., PLCs) requires complex engineering.

- High Energy Consumption: Traditional hydraulic pumps may have lower efficiency compared to electric systems.

Maintenance and Safety

- Multi-Stage Filtration: Use of magnetic and micron filters to remove contaminants.

- Fluid Temperature Monitoring: Installation of coolers or heaters to maintain optimal oil temperature.

- Periodic Inspections: Checking for leaks, cylinder wear, and control valve performance.

- Use of Compatible Fluids: Replacing conventional oils with non-toxic fluids in food or pharmaceutical environments.

- Operator Training: Familiarity with safety protocols when working with high pressures.

Innovations and Future Trends

- Smart Hydraulics:

- Integration of IoT sensors for real-time monitoring of pressure, temperature, and fluid quality.

- Predictive Maintenance using data analyzed by artificial intelligence.

- Energy-Efficient Systems:

- Use of variable displacement pumps to reduce energy consumption.

- Energy recovery in injection or press systems (e.g., storing energy in accumulators).

- Electro-Hydraulics:

- Combining electric motors with hydraulic systems for increased precision and reduced noise.

- Servo hydraulic systems with fast response for industrial robots.

- Advanced Materials:

- Manufacturing cylinders from lightweight composites resistant to corrosion and wear.

- Nano-coatings to extend the lifespan of components exposed to corrosive fluids.

- Full Automation:

- Integrating hydraulics with collaborative robots (Cobots) and machine vision systems.

- Use of Digital Twin technology for simulation and optimization of system performance.

The Role of Hydraulics in the Future of Manufacturing

Despite the growth of electric and pneumatic technologies, hydraulics will remain at the heart of manufacturing industries due to their unparalleled power and reliability under heavy loads. It is predicted that hydraulic systems, with the integration of artificial intelligence, IoT, and advanced materials, will move towards higher efficiency, reduced energy consumption, and full environmental compatibility. The focus on smart automation and lean manufacturing will further strengthen the role of hydraulics in Industry 4.0.

افزودن دیدگاه