Hydraulic Pump ــــ ⏱ 3 min read

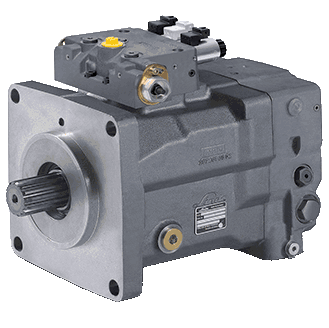

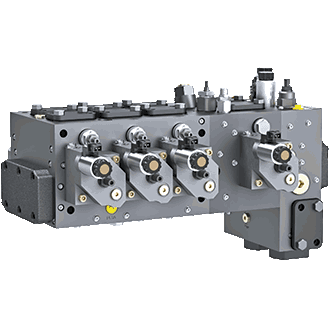

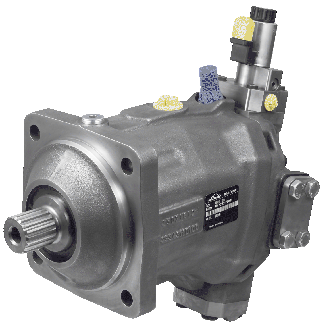

Hydraulic Pump is a core component of hydraulic systems, responsible for converting mechanical energy into hydraulic energy. By generating flow and pressure in hydraulic fluid (typically oil), it provides the force needed to operate cylinders, hydraulic motors, and other system components.

Types of Hydraulic Pumps

Hydraulic pumps are broadly classified into three main categories:

- Gear Pumps:

- External Gear Pump: Consists of two meshing gears inside a housing. As the gears rotate, fluid is drawn in and pushed out.

- Internal Gear Pump: Uses an inner rotor and outer idler gear to transfer fluid.

- Vane Pumps:

- Balanced Vane Pump: Features vanes mounted on a rotor that rotates eccentrically within a housing. The vanes extend and retract to move fluid.

- Unbalanced Vane Pump: Simpler design with lower pressure capacity compared to balanced vane pumps.

- Piston Pumps:

- Axial Piston Pump: Pistons are aligned parallel to the drive shaft. Rotation causes pistons to reciprocate, displacing fluid.

- Radial Piston Pump: Pistons are arranged radially around a central drive shaft.

Applications

Hydraulic pumps are used in industries such as:

- Industrial Machinery: Hydraulic presses, CNC machines, and cutting equipment.

- Construction: Excavators, cranes, and loaders.

- Aerospace: Flight control and landing gear systems.

- Marine: Ship steering systems and hydraulic equipment.

- Agriculture: Tractors and farming machinery.

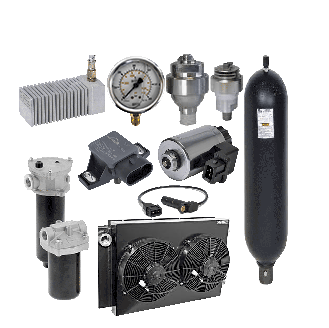

Key Components

- Driver (Motor): Provides mechanical energy (electric motor, internal combustion engine).

- Casing: Houses internal components and directs fluid flow.

- Gears/Vanes/Pistons: Mechanism for fluid displacement.

- Seals: Prevent leaks and maintain pressure.

Advantages

- High Power Density: Delivers significant force in compact designs.

- Precise Control: Adjustable speed and force for accurate operations.

- Durability: Long lifespan with proper maintenance.

- Versatility: Suitable for diverse environments and applications.

Disadvantages

- High Costs: Initial investment and maintenance expenses.

- Fluid Leaks: Risk of oil leakage and environmental contamination.

- Heat Generation: Potential overheating during prolonged use.

Maintenance Tips

- Use Quality Hydraulic Fluid: Ensure proper viscosity and filtration.

- Regular Inspections: Check for wear, leaks, or pressure drops.

- Seal Replacement: Address leaks promptly to avoid system failure.

- Temperature Monitoring: Prevent overheating with cooling systems.

Working Principle

A hydraulic pump takes mechanical energy from a power source (e.g., electric motor) and converts it into hydraulic energy by pressurizing fluid. This pressurized fluid is then directed to actuators (cylinders, motors) to perform work, such as lifting loads or moving machinery parts.

Key Industries

- Heavy Machinery: Excavators, loaders, and bulldozers.

- Automotive: Power steering and braking systems.

- Agriculture: Tractors and harvesters.

- Manufacturing: Hydraulic presses and automation systems.

Let me know if you need further details on specific pump types or applications!

افزودن دیدگاه