Hydraulic Motor ــــ ⏱ 3 min read

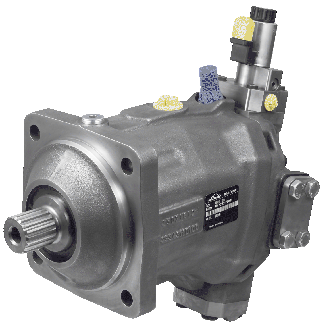

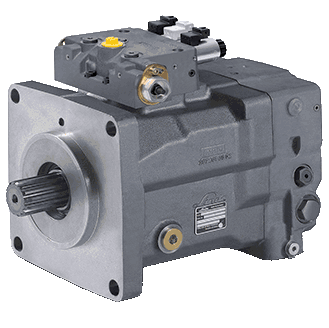

Hydraulic Motor (also known as a Hydromotor) is a mechanical device that converts hydraulic energy (energy from pressurized fluid) into rotational mechanical energy. It operates inversely to a hydraulic pump (which converts mechanical energy into hydraulic energy). Hydraulic motors are used in hydraulic systems to power rotational motion in industrial machinery, heavy equipment, robotics, and other systems.

Types of Hydraulic Motors

Hydraulic motors are categorized based on their design and operation:

- Gear Motor:

- Uses two gears (a driving gear and a driven gear).

- Simple, cost-effective, and suitable for medium-pressure/torque applications.

- Example: Agricultural machinery hydraulic systems.

- Piston Motor:

- Utilizes pistons driven by fluid pressure.

- Handles high pressure and torque.

- Subtypes: Bent Axis and Radial Piston Motors.

- Example: Hydraulic cranes or ship power transmission systems.

- Vane Motor:

- Employs vanes inside an oval-shaped chamber.

- Quiet operation but unsuitable for high-pressure applications.

- Example: High-speed industrial hydraulic systems.

- Gerotor Motor:

- Uses an internal and external gear set to generate motion.

- High efficiency for medium-pressure tasks.

- Example: Automotive hydraulic systems.

Applications

- Power transmission in heavy machinery (excavators, loaders, bulldozers).

- Cranes and hydraulic lifts.

- Marine systems (steering controls).

- Industrial robots and production lines.

- Tunneling and drilling equipment.

- Power plants and petrochemical systems.

Advantages

- High torque output, even at low speeds

- Precise control over speed and torque via fluid pressure/flow

- Shock load resistance and durability

- Reliable operation in harsh environments (heat, moisture, dust)

Disadvantages

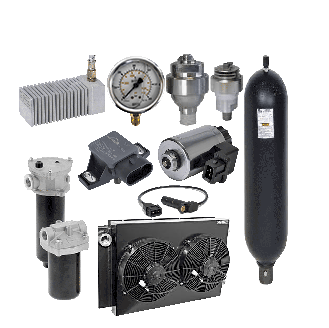

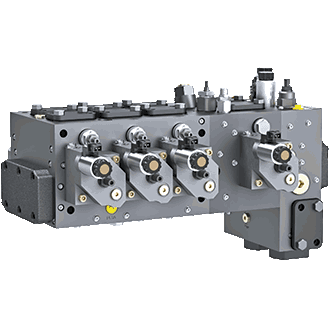

- Requires a complex hydraulic system (pump, reservoir, piping)

- High maintenance costs (fluid changes, seals, filters)

- Risk of fluid leaks and environmental contamination

- Lower efficiency compared to electric motors in some scenarios

Key Selection Criteria

- Maximum operating pressure (Bar/psi)

- Torque requirements (Nm/lb-ft)

- Rotational speed (RPM)

- Fluid flow rate (L/min or GPM)

- Hydraulic fluid type (mineral oil, synthetic oil)

Hydraulic Motor vs. Electric Motor

| Feature | Hydraulic Motor | Electric Motor |

|---|---|---|

| Power Source | Pressurized Fluid | Electricity |

| Low-Speed Torque | Very High | Limited |

| Shock Load Tolerance | Excellent | Moderate |

| System Complexity | Requires Hydraulic Circuit | Simple |

| Efficiency | 85-90% | 90-95% |

Maintenance & Safety Tips

- Use hydraulic filters to prevent fluid contamination

- Fix leaks promptly

- Monitor system pressure and temperature

- Replace hydraulic fluid periodically

Let me know if you need further technical details!

افزودن دیدگاه