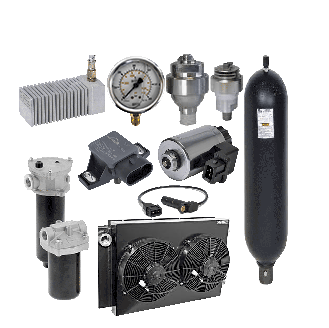

Accessories ــــ ⏱ 3 min read

Hydraulic systems consist of various components used to transmit power and motion through pressurized fluid (usually oil). Hydraulic accessories play a vital role in the proper functioning of these systems. Below are some of the most important hydraulic accessories and their descriptions:

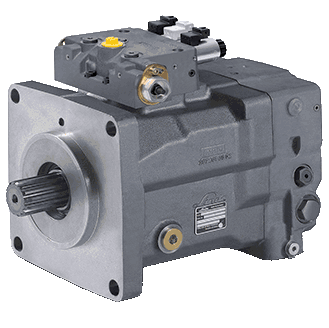

Hydraulic Pump

- Function: Converts mechanical energy into hydraulic energy by creating a flow of pressurized fluid.

- Types:

- Gear Pump

- Piston Pump

- Vane Pump

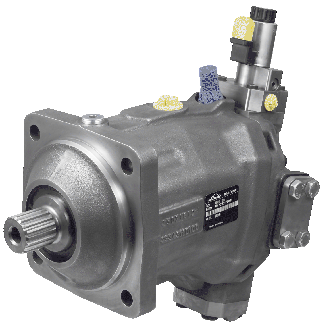

Hydraulic Motor

- Function: Converts hydraulic energy into rotational motion.

- Types: Gear motor, piston motor, vane motor.

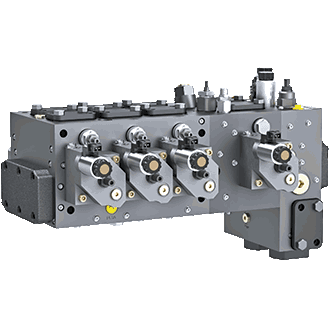

Control Valves

- Function: Controls the direction, pressure, and flow rate of the fluid.

- Main Types:

- Directional Control Valve: Determines the flow path.

- Pressure Relief Valve: Limits system pressure.

- Flow Control Valve: Regulates the speed of cylinders or motors.

Hydraulic Cylinder

- Function: Converts hydraulic energy into linear motion (push or pull).

- Applications: Cranes, excavators, industrial presses.

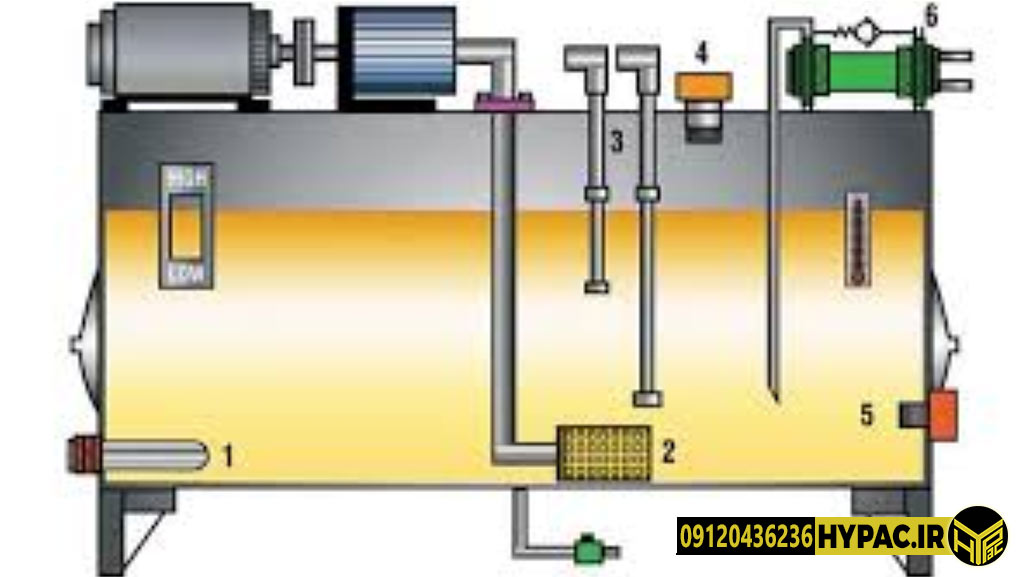

Hydraulic Reservoir

- Function: Stores hydraulic fluid, cools the oil, and separates air and contaminants.

Filters

- Function: Removes contaminants from the oil to prevent damage to components.

- Installation: On the pump inlet or return line.

Pipes and Hoses

- Function: Transfers fluid between components.

- Material: Stainless steel, high-pressure plastic, or reinforced rubber.

Fittings

- Function: Provides secure connections for pipes, hoses, and other components.

- Types: Quick couplings, threaded fittings, flanges.

Seals

- Function: Prevents oil leakage and maintains system pressure.

- Types: O-ring, gasket, wiper seal.

Accumulator

- Function: Stores hydraulic energy and reduces pressure fluctuations.

- Applications: Shock absorption, emergency pressure supply.

Pressure Gauges and Sensors

- Function: Displays pressure, temperature, and other system parameters.

Coolers and Heaters

- Function: Regulates fluid temperature to prevent overheating or freezing.

Key Maintenance Tips

- Use hydraulic oil with the appropriate grade.

- Replace filters and seals on time.

- Regularly inspect hoses and fittings to prevent leaks.

- Prevent fluid contamination (Contamination Control).

Common Applications of Hydraulic Systems

- Industrial machinery (presses, plastic injection machines).

- Construction equipment (excavators, loaders).

- Aircraft and hydraulic steering systems.

By selecting high-quality components and performing regular maintenance, the lifespan of hydraulic systems can be significantly extended.

افزودن دیدگاه